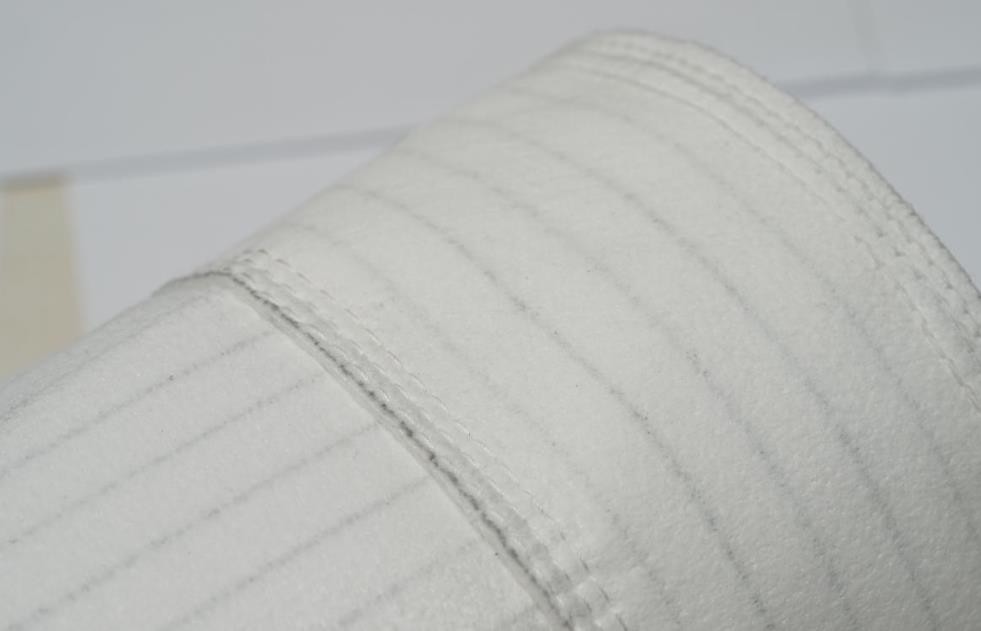

Anti-static Polyester Filter bags

The Anti-static polyester Filter Bags is made of normal temp needle felt filter media with grid stainless antistatic fiber scrim or line type anti-static scrim in side to meet electrostatic discharge sparks or external ignition,as the general industrial dust can easily cause explosions and fires when the concentration reaches a certain level (explosion limit) .

Briefly Introduction:

Polyester stripe anti-static needle felt with water and oil proof is suitable for the high moisture content of the occasion,such as iron and steel plant blast furnace coal powder,cement plant, power plant coal handling system.

As the general industrial dust can easily cause explosions and fires when the concentration reaches a certain level (explosion limit) .If the dusts need to be collected in a Filter Cartridges or a dust Filter bags, it is required that the filter material of the dust filter bags with anti-static effection.Our company produced anti-static needel felt media or said filter cloth according to the needs of blast furnace gas coal dust collection and cement mill coal dust collection and other industries.

Features:

High strength and low elongation of industrial wire cloth, so that a substantial increase in strength.

Selection of fine denier fiber, narrow aperture, high porosity, high filtration accuracy.

Selection of superior polyester fiber, acid and alkali resistance have been enhanced.

Surface treatment is more smooth, has the effect of the surface filter membrane filter.

Running resistance is small, save energy

Application:

The fume and smoke treatment and particle removing system in metallurgy plant.

Smoke filtration in garbage burning, coal-feed boiler.

Asphalt concrete mixture, cements, ceramics, building materials.

Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

Specification:

| Fiber Material | Polyester Staple | |||

| Scrim | Anti-static Scrim | |||

| Thickness | 1.8mm | |||

| Unit Weight | 500g/m2 | |||

| Air Permeability | 130-180L/(dm2*min) | |||

| Surface Resistivity | MΩ | 310-335 | ||

| Volume Resistivity | MΩ | 57-63 | ||

| Tensile Strength | MD(N) | ≥ | 1000 | |

| CD(N) | ≥ | 1300 | ||

| Break Elongation | MD(%) | < | 35 | |

| CD(%) | < | 35 | ||

| Working Temp | Continu ous(℃) | 130 | ||

| Peak(℃) | 150 | |||

| Chemical Properties | Acid-resistant | Moderate | ||

| Alkali-resistant | Bad | |||

| Oxidation-resistant | Good | |||

| Hydrolysis-resistant | Bad | |||

| Ultraviolet resistant | Good | |||

| Finishing | Heat Setting | Singe | Calendar | Chemical Coating |

| Products with desired unit weight, thickness, and finishing styles can be provided according to customers’ requirements. | ||||

INQUIRY

CATEGORIES

CONTACT US

Contact: HEIDI CHEN

Phone: 8618758291236

E-mail: hl106@hlfilter.com

Whatsapp:8618758291236

Add: 16F Wanda Plaza A,Gongshu Distrit ,Hangzhou ,China.