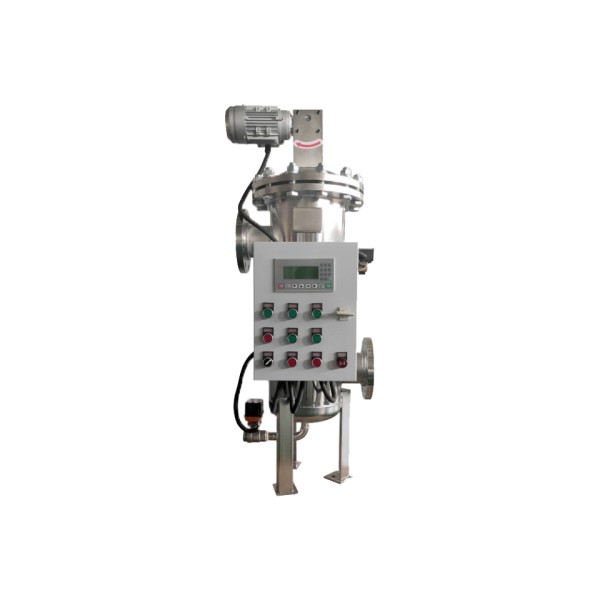

Self cleaning Filter Housing

The automatic scraper type Self Cleaning Filter Housing is composed of motor reducer, stainless filter housing, filter screen, scraper combined cleaning system, PLC controller and electric sewage valve. It has the advantages of overcoming the traditional bag filter housig's shortcomings, such as small amount of pollution, easy blockage and frequent replacement of filter elements and Filter Bags. The raw material medium enters the filter through the feed port, from the inside to the outside, is filtered through the gap of the filter screen, the filtered raw material flows from top to bottom to the lower discharge port, and the impurities larger than the filter screen are intercepted and left behind. After running for a certain period of time, the filter gap is blocked by impurities, and when the pressure difference reaches the preset value, the PLC monitors the signal and sends out instructions. The geared motor drives the rotating scraper to automatically clean the dirt attached to the filter and maintain the filter. Filter function, the filter gap is unblocked; when the impurities at the bottom of the filter increase, as long as the bottom of the slag cutting blade is opened, the impurities will be discharged smoothly and the system pressure will remain normal. The scraper type self-cleaning filter has a reasonable scraper layout and an optimized scraping angle. Driven by the geared motor, the rotating scraper scrapes off the impurities in the filter gap in time, eliminating the trouble of dismantling and washing the filter, and keeping the raw materials unimpeded and filtered. The scraper system is a self-cleaning filter composed of fixed blades, PTFE scraper brush type combined cleaning and spring. The spring pressure compensation is reasonable and the wear of the filter screen is minimized.

Technical Data Of Filter Housings

| HL Reference | HL18 | HL25 | HL41 | HL61 | HL81 | HL118 |

| Filter area (m2) | 0.18 | 0.25 | 0.41 | 0.61 | 0.81 | 1.18 |

| Inlet Diameter | DN25 | DN50 | DN80 | DN100 | DN100 | DN125 |

| Outlet Diameter | DN25-DN80 | |||||

| Remvoal Rating: | 1-1000µm | |||||

| Max. Pressure | 1.0Mpa (accept customized) | |||||

| Cleaning pressure differential | 50-100Kpa | |||||

| Pressure differential gauge | 0-200 | |||||

| Designed Temp (0c) | sandblast/polishing surface | |||||

| Blade Material | PTFE | |||||

| Shell Sealing Material | NBR, EPDM, VITON, Silicone rubber, FEP costing silicone rubber | |||||

| Filter Elements Sealing Mat | NBR, EPDM, VITON, Silicone rubber, FEP costing silicone rubber | |||||

| Drain Valve | Pneumatic Valve, single or double effect type, 304 316L | |||||

INQUIRY

CATEGORIES

CONTACT US

Contact: HEIDI CHEN

Phone: 8618758291236

E-mail: hl106@hlfilter.com

Whatsapp:8618758291236

Add: 16F Wanda Plaza A,Gongshu Distrit ,Hangzhou ,China.