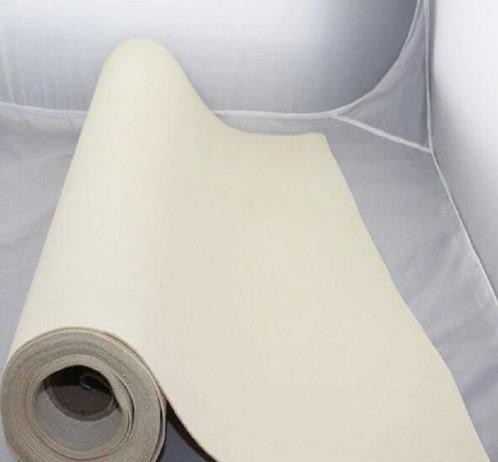

PPS Needle Felt Media

PPS Needle Felt Media is a kind of High Temp Needle Felt Air Media, FZ Filter PPS is with selected Toray fiber materials, and produced with advanced equipment with loosen and needle techniques,

Briefly Introduction:

PPS Needle Felt Media is a kind of High Temp Needle Felt Air Media, HL Filter PPS is with selected Toray fiber materials, and produced with advanced equipment with loosen and needle techniques,

With decades of experience in needling, we manufacture a wide range of Polyphenylene sulfide (PPS) needle felts (also called Ryton) with high dust-holding capacity and good air permeability,and can produce different PPS filter cloth and Filter Bags according to the working conditions, such as 100% PPS, PPS+PTFE scrim, PPS+PTFE mixed fiber cloth, PPS Needle Felt Cloth is good resistance to hydrolysis, alkalies and acids makes them an alternative to PTFE fibers under certain conditions. PPS Needle Felt is easily oxidized at increased temperature. PPS fiber can keep intensity completely and bear chemistry natural inherently, keep good filtration performance among the abominable environment, reach ideal service life. In coal boiler, rubbish incinerator, power plant of fly ash filtering of pulse clear dust catcher.

PPS filter felts are an ideal filtration material. PPS filter felt is one of the main filter material able to bear the high temperature according to processed of production technology and artificial material of other high-temperature filter felt. Selected Toray fiber, using advanced equipment to loosen.

Features:

High termperature needle punched felt

Excellent chemical resistance (except for oxidation)

Ability to operate effectively on applications with O₂ content up to 9%.

Works well in high moisture content applications and where dew point crossings are common.

This media is suited for applications where emissions standards are tight.

Applications:

Asphalt & Aggregate

Waste Incineration

Chemicals & Pharmaceuticals

Metals & Foundry

Food & Beverages

Custom OEM Applications

Specification:

| Fiber Materials | PPS-Polyphenylene Sulfide | |

| Scrim | PPS | |

| Standard Finish Options | Heat Set, Singed, Glazed, PTFE membrane, Water and oil proof | |

| (Special surface treatments available) | ||

| Weight (g/m2) | 400-650 | |

| Thickness (mm) | 1.3-1.8 | |

| Air Permeability (m³/m².min@200PA ) | 10--16 | |

| Tensile Strength (N/5CM) | Warp | 900 |

| Weft | 1200 | |

| Tensile Elongation (%) | Warp | ≤25 |

| Weft | ≤45 | |

| Thermal Shrinkage (%) at max continuous temp. | Warp | ≤1 |

| Weft | ≤1.5 | |

| Max. Operating Temperature oC | Continuous | 190 |

| Surge | 200 | |

| The data are based on laboratory conditions. | ||

| Testing based on specific operating conditions of each installation is recommended. | ||

INQUIRY

CATEGORIES

CONTACT US

Contact: HEIDI CHEN

Phone: 8618758291236

E-mail: hl106@hlfilter.com

Whatsapp:8618758291236

Add: 16F Wanda Plaza A,Gongshu Distrit ,Hangzhou ,China.